3D printer

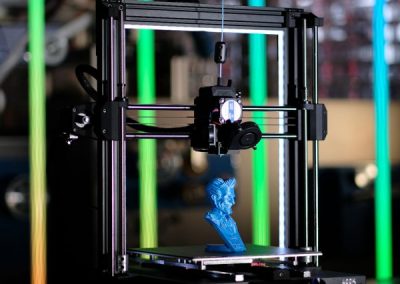

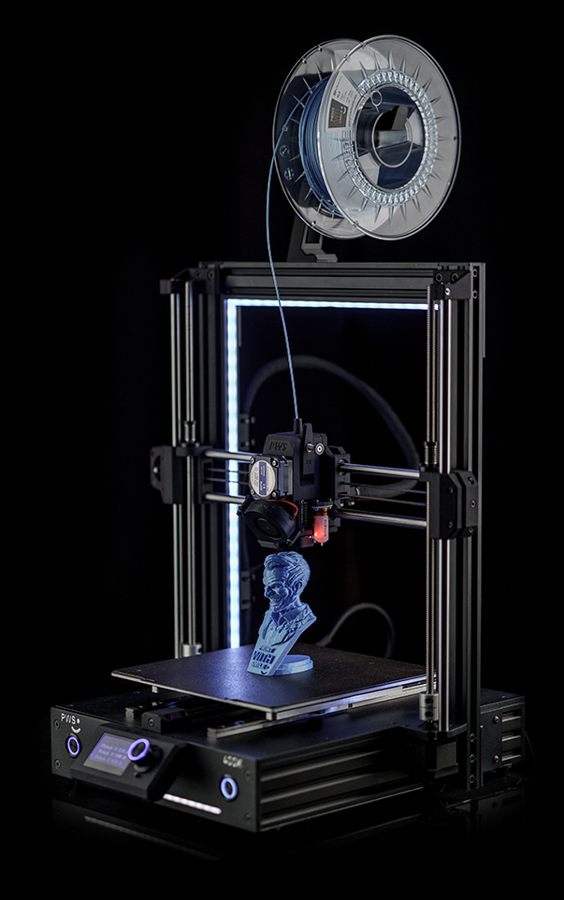

PWS400K

Introducing the PWS400K 3D FDM printer

This 3D printer was created thanks to cooperationis between Ready3D and 400K. From 2023 onwards, we took over the serial production under the brand PRINT WITH SMILE.

Unrivalled

The printer allows normal print speed of over 100mm/s with non-printing movements of 400mm/s, all without sacrificing print quality. It achieves this with Klipper firmware, rigid and durable construction, CNC milled alu parts and MJF printed parts – in collaboration with ABR3DPRINT.

fine electronics

fast printing

precision printing

PWS400K 3D printer parameters

List of all parameters

- Normal print speed 100 mm/s+, maximum speed 400mm/s acceleration 7500 mm/s2

- Opensource firmware Klipper with Fluidd/ Mainsail web interface, LCD help menu in Czech

- Network connection via LAN cable or Wifi

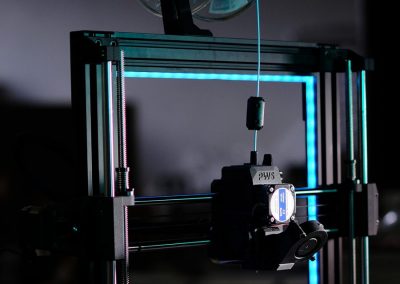

- RGB LED lighting in the frame with the ability to change the light intensity and light notifications.

- Pre-installed plugin for remote printer management and monitoring. After registration to

next.karmen.tech

the user will be able to control the 3D printer using the Karmen cloud app from anywhere, even from a mobile phone. If a webcam is connected, Karmen also enables automatic detection of printing errors and notification of the user if something goes wrong. - Relay for automatic shutdown of the printer in case of print completion, detected error or malfunction, which increases not only safety but also user comfort.

- Parts printed by MJF technology from highly temperature-resistant PA12 (polyamide) material, allow the printer to be placed in a closed box and subsequent printing at high temperatures.

- Automatic alignment of the print pad using the BL touch sensor

- Rigid all-metal frame made of 2040, 2060 alu profiles. Base, front and rear plate made of 6mm thick ALU, all in semi-matte black comaxit lacquered finish

- Printing area 235 x 235 x 260(W)mm

- Magnetic bed with granular plate PWS

- 10 mm hardened ground rods for X and Z axes,

- STEPPERONLINE 1.5A stepper motors NEMA 17 (X,Y,Z)

- STEPPEROLINE 1.0A NEMA 17 pancake motor (extruder)

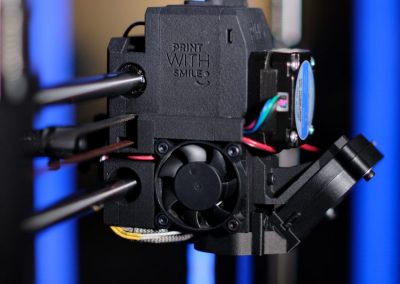

- Direct extruder with 50:17 gear ratio with filament sensor

- All materials can be printed at temperatures up to 300 degrees. Czech made hotend from TECH-MODEL with copper heatblock, titanium heatbreak and aluminium heat sink. Optional Alternative

RAPTOR Hot-end®

of the Czech manufacturer PROTOPRINT. - Genuine belts from Gates

- MGN12 linear guide for Y axis,

- MISUMI quality linear bearings LM10UU and LM10LUU for X and Z axis

- 24V MEAN WELL LRS400-24 (printer power supply), 5V MEAN WELL RS-25-5 (permanent RPI power supply)

- Orange Pi 3 LTS + 32Gb card (USB) 32bit motherboard with TMC2209 UART drivers (sensorless homing XY)

- 12864 neopixel display with backlight colour change

- 3 x USB slot for camera connection

- Preparation for printing in a box with a temperature of up to 50 degrees (electronics cooled in the base from below)

- Printer weight 15 kg

- Printer dimensions: width 48 cm / depth 38 cm / height without spool holder 53 cm – spool holder 15 cm

- dimensions of the shipment (box): 56 x 56 x 68 cm

Listing of individual parameters

Print speed

Normal print speed 100 mm/s+, maximum speed 400mm/s acceleration 7500 mm/s2

Opensource firmware Klipper

Opensource firmware Klipper with Fluidd/ Mainsail web interface, LCD help menu in Czech

Connectivity

Network connection via LAN cable or Wifi

Light notifications

RGB LED lighting in the frame with the ability to change the light intensity and light notifications.

Pre-installed plugin for remote printer management and monitoring

After registration to

next.karmen.tech

the user will be able to control the 3D printer using the Karmen cloud app from anywhere, even from a mobile phone. If a webcam is connected, Karmen also enables automatic detection of printing errors and notification of the user if something goes wrong.

Automatic printer shutdown

Relay for automatic shutdown of the printer in case of print completion, detected error or malfunction, which increases not only safety but also user comfort.

Durable materials for printing at high temperatures

Parts printed by MJF technology from highly temperature-resistant PA12 (polyamide) material, allow the printer to be placed in a closed box and subsequent printing at high temperatures.

BL touch sensor

Automatic alignment of the print pad using the BL touch sensor.

Construction from ALU profiles

Rigid all-metal frame made of 2040, 2060 alu profiles. Base, front and rear plate made of 6mm thick ALU, all in semi-matte black comaxit lacquered finish

Printing area

Printing area 235 x 235 x 260(W)mm

Magnetic bed with granular plate PWS

Quality X and Z axes

10 mm hardened ground rods for X and Z axes,

Engines

STEPPERONLINE 1.5A NEMA 17 (X,Y,Z) stepper motors.

STEPPEROLINE 1.0A NEMA 17 pancake motor (extruder)

Direct extruder

Direct extruder with 50:17 gear ratio with filament sensor

All materials can be printed at temperatures up to 300 degrees

Czech made hotend from TECH-MODEL with copper heatblock, titanium heatbreak and aluminium heat sink. Optional Alternative RAPTOR Hot-end® from the Czech manufacturer PROTOPRINT.

Belts and linear guides

Genuine Gates belts.

MGN12 linear line for Y axis.

Bearings

MISUMI quality linear bearings LM10UU and LM10LUU for X and Z axis.

Source :

24V MEAN WELL LRS400-24 (printer power supply), 5V MEAN WELL RS-25-5 (permanent RPI power supply)

Motherboard with memory

Orange Pi 3 LTS + 32Gb card (USB) 32bit motherboard with TMC2209 UART drivers (sensorless homing XY)

3 x USB slot for camera connection

Display

12864 neopixel display with backlight colour change

Preparing for printing in the box

Preparation for printing in a box with a temperature of up to 50 degrees (electronics cooled in the base from below)

DIMENSIONS AND PACKAGING

- printer dimensions: width 48 cm / depth 38 cm / height without spool holder 53 cm – spool holder 15 cm

- dimensions of the shipment (box): 56 x 56 x 68 cm

- Printer weight: 15 kg

Downloads

Firmware, documents, manuals, settings, print profiles and print models, hints and tips.

CE certification

Manual CZ

Manual EN

Profiles for PWS400K – PrusaSlicer 2.7

MANUAL WIFI connect

xyzCalibration cube PWS400k_PETG

xyzCalibration cube PWS400K_PLA

Eiffel Tower PWS400K_PLA

Filament holder PWS

Camera door PWS400K_PLA Creative Commons@voyczech

PWS400K_PETG Creative Commons@voyczech